Day 1 - 25 October 2019 (Friday)

To kickstart the project management week, I first watched a video on project management on the fabacademy website.

In this tutorial, Neil covered the basics of tools that we’ll be using during our project work – this may be for synchronisation, version control or web development.

However, the main focus was on how to manage your project well. For this he covered 7 basic principles:

1. Triage - while working through the project, I need to pick projects that lie at the intersection of my ambition and what can be accomplished.

2. Demand and supply side time management - I need to balance between tasks that are necessary but take a lot of time, or fix the time and decide the tasks and schedule work around that.

3. Serial versus parallel development - when each project is broken down into tasks, in the interest of time, work on parallel tasks most of the time and serial tasks only when necessary. This is to make sure that anyone task does not block you from completing the project.

4. Spiral development - do not think of projects as something that will develop in a linear fashion. Think of it as a spiral or a loop - where each task finishes and opens into the next task.

5. Bottom up versus top down debugging - bottom up debugging is starting from scratch and adding few parts at a time to a task to test if its working, while top down is removing parts from a system to see what should be removed for the task to work.

6. Hierarchy and modularity - projects should be as modular as possible.

7. Document as you work - don’t wait until the end of the week to finish your documenting your learnings and your work.

Markdown tutorials that I used to learn markdown syntax:

All these tutorials and guides on markdown have the same information, but reading it repetitively has helped me recollect the syntax for text formatting a lot more quickly.

After reading the tutorial, I fixed some formatting issues on my website. For this, I downloaded Github Desktop and sublime text editor. The advantages of downloading these two are as follows: firstly, Github desktop will allow me to clone a local version of my online repository, making it available for me offline – even enabling me to add files and documents to the local file, which will synchronise with the online website when I enable it, and secondly sublime text editor will allow me to edit the content of the website offline – so I don’t have to have a steady internet connection while working.

In the first version of my website, for Day 1, I had listed out the machinery in the digital fabrication workshop, with a description of the capabilities of these machines, and a picture. However, the list was not working on the website. While I wanted them to be listed 1,2,3,4… it was showing as 1,1,1,1. For some reason that wasn’t immediately obvious to me, the code was not able to read it as a continuous list.

After multiple iterations and attempts, I finally realised that there was an empty line between the list item title and the description. So I removed the empty line between the title and the description and between the description and the picture. This solved one problem – so now the list was working, with the numbers in a neat progression. However, because of the lack of a gap between the description and the picture, the picture was coming up in between the description making it difficult to read continuously. To correct this, I inserted two spaces after the last sentence of the description. This automatically pushed the picture into a new line. I also indented the description and the picture with a >.

For integrating github, the online version, with githu desktop, there are a number of steps:

- You have to first “Pull” any changes made on github onto github desktop.

- The changes that have been made on sublime text editor have to be saved.

- “Commit to master” the changes made in the content with sublime text editor – this commit button is available on github desktop.

- “Push origin” to github - this command button is also available on github desktop for you to move the changes you’ve made locally onto the online version.

Once you push the changes, and refresh the website, the website is updated with all the changes you’ve made.

Day X - 26 October 2019 (Saturday)

Home experiments - Making cornflour-based bioplastic at home

On Friday evening, while reading up on bioplastics, I came across videos on ‘how to make bioplastic at home.’ It looked like something that would be easy to make, given most of the ingredients were in my kitchen pantry.

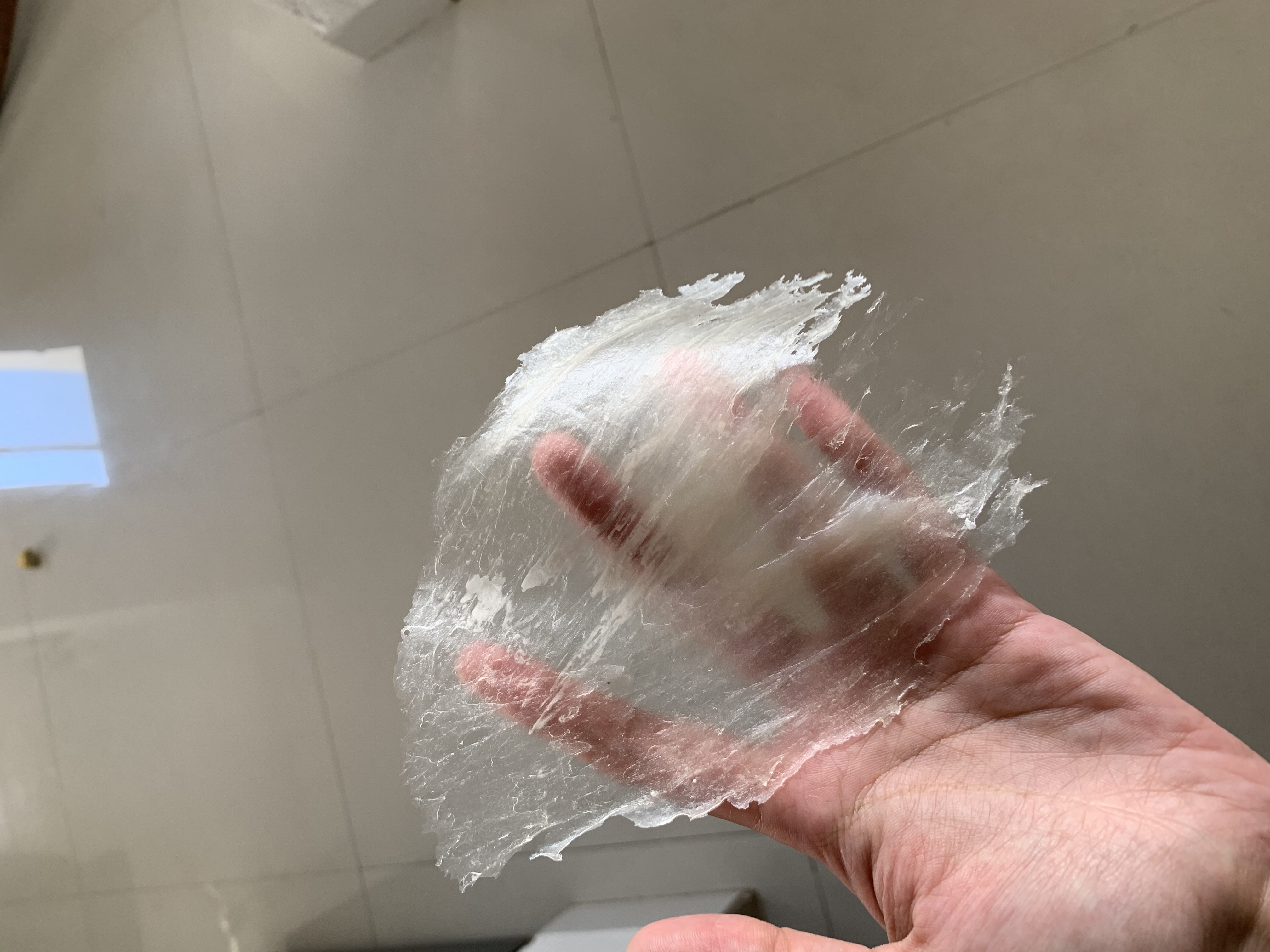

Using the instruction from a Green Plastics Youtube video, I made bioplastic with cornflour as the main ingredient – cornflour is maize starch. The other ingredients I used were water, gylcerine, and vinegar. The recipe called for plain vinegar, but I had only apple cider vinegar and I decided to use it anyway.

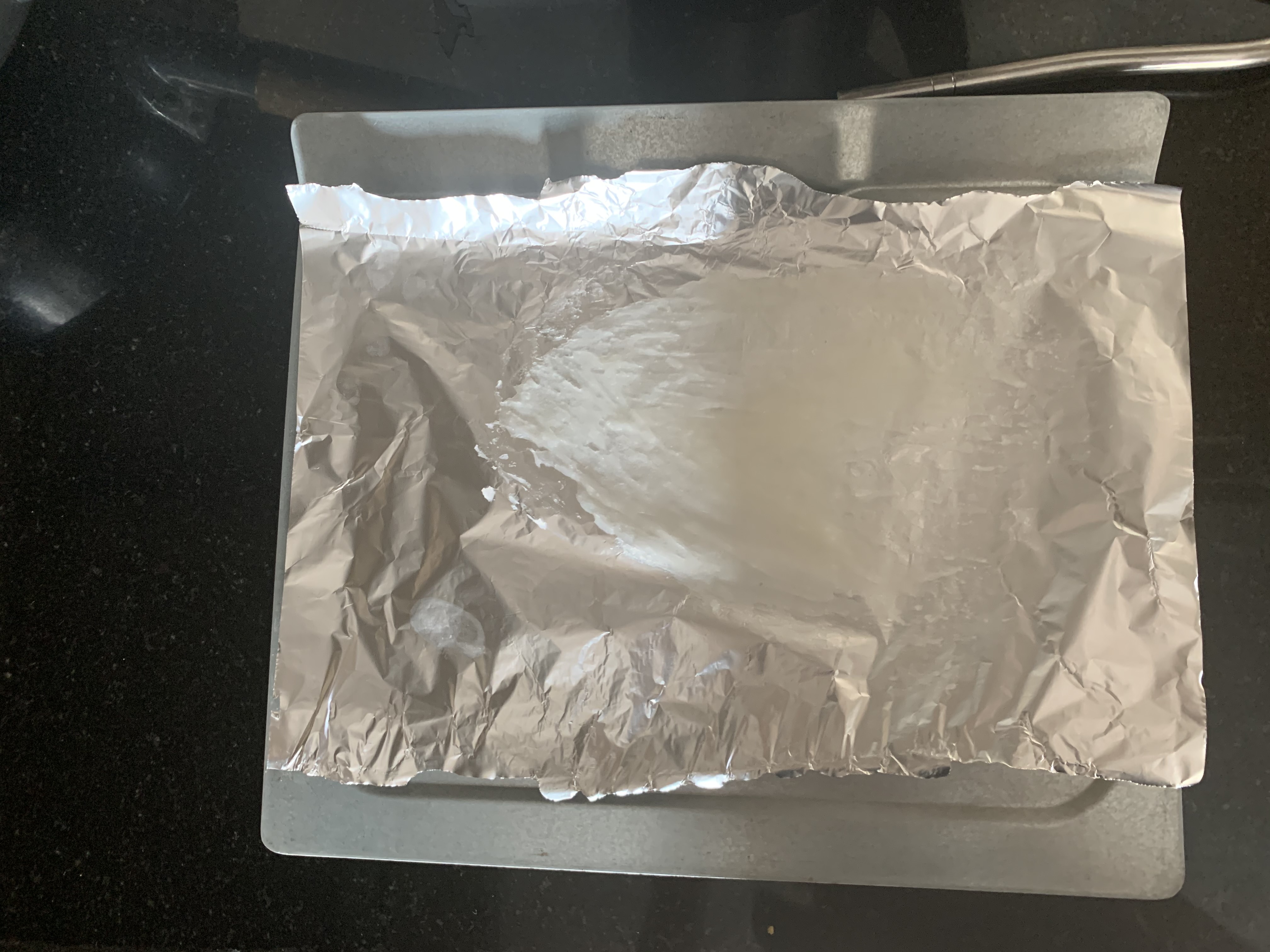

This is what the bioplastic looked like when I just took it hot off the stove and spread it on a aluminium foil.

I made this at around 10am on Saturday morning, and kept the foil with the bioplastic in a safe, cool place away from moisture to ensure that the bioplastic sets thoroughly. I checked around 10am on Sunday morning, 24 hours after I’d made it, and it had cooled down completely and set as well. It had a pungent apple cider vinegar smell, which is to be expected I suppose. The texture was a little brittle – when I tried stretching the bioplastic sheet, it tore the sheet. The sheet feels a little rubbery as well, and not the typicaly plastic texture that I expected.

This was a good start to understanding materials, and I’m looking forward to making more of this bioplastic with other plant starch varieties.

Day 2 to Day 4 - 28 October 2019 to 31 october 2019, Monday to Thursday

Ideas for project work:

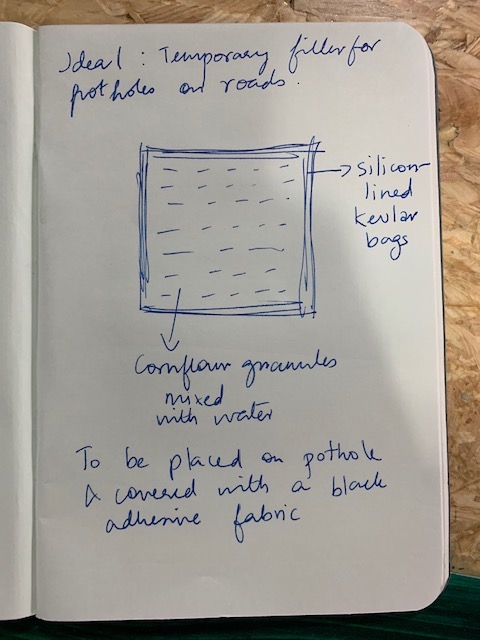

__Idea 1: Temporary filler for potholes on roads__

Motivation for idea: I’ve been hearing a lot of people complain about bad roads in Bangalore, making driving uncomfortable and even fatal at times for people with back problems or any other physical ailments. Since I’m pregnant, my doctors advised me to travel safely, which means not taking transport modes that shake a lot – I have been able to do this only in the metro. Driving on the road or even taking an auto has made me more susceptible to the potholes and I keep wondering if there is a simple and economical quick-fix, even if it is only a temporary one.

Has it been already done? If so, is my work going to add any additional value to an existing one or is it going to be a replication?

Yes, there is an existing solution that uses granules of cornstarch in silicon lined kevlar bags. How it works is this bag is filled with water and cornstarch in a certain proportion, zipped up and placed on the pothole, and covered with a black adhesive fabric. As soon as a car or vehicle drives over it, it immediately solidifies, and fills out the hole.

What is it going to look like? (A sketch)

Other comments

While this is patented, I’d like to see if I can figure out how to recreate this in India. This is still fairly new, and has not been tried and tested in many parts of the world. This may be a good temporary solution to look into, until city municipalities fix the potholes permanently.

__Idea 2: Sustainable food packaging for restaurants and other food delivery services__

Motivation for idea: For a few months now, I’ve been mulling with the idea of possible business ideas to pursue. On one evening, after a dinner get together with around 15 people, we found ourselves in the kitchen with 20 or more individual plastic food containers. It left me feeling uneasy and uncomfortable knowing there was nothing I could do about it except dump them in all the dry waste bin. I’ve tried to be responsible while using plastic. For instance, at one point in time, we were buying large 25litre bisleri cans for our daily water consumption. Once they were empty, I would then cut out their mouths, widening them, drill small holes at the bottom, add soil to it and grow plants in them – This was particularly useful for fruit saplings like papaya, which I have since then transplanted into the ground since they required more space and a deeper level of soil.

However, I could not do the same with these plastic food containers. I’ve tried reusing them in the past, but washing and reusing them has just resulted in more of them accummulating in the kitchen, which is also not desirable for me. So, how could I help solve this problem for the businesses that are currently using plastic food packaging?

While conducting some secondary research online, I discovered that there were companies that were providing sustainable packaging alternatives like making plastic containers out of bagasse or cornstarch (what are commonly referred to as bioplastics) but these solutions had not scaled up as successfully as they wanted.

On speaking to some food delivery companies, I learnt many interesting things:

- Bioplastics and sustainable food packaging options are not cost effective - food delivery companies do not want to pay for the additional premium, and consumers don’t want to pay either.

- Current spend on by food delivery companies on packaging is 15% of total cost and 20-30% of total cost for delivery

- On Bagasse - a lot of people have tried bagasse - for an Indian scenario, it might not work since there are liquid food items - any steam trapped inside can make the dry dishes soggy.

- Cornstarch has also not worked successfully for Indian meals.

What are some of their requirements?

- lightweight

- spill proof

- plastic range (three compartment, four compartment) - INR 15

- reusable packaging - turmeric wont go

- disposable

- cornstarch - is that sustainable

- no need for reverse logistics

- sturdy enough to be stacked one on top of another

Has it been already done? If so, is my work going to add any additional value to an existing one or is it going to be a replication?

There is some on-going research and development in this area, but there has not been a single product or service or product that has been able to implement sustainable packaging at scale.

What is it going to look like? (A sketch)

It will look like existing packaging material, I think, but the material may be different.

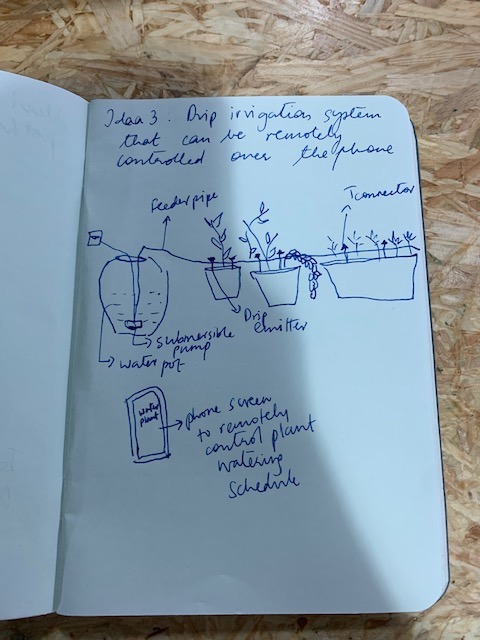

__Idea 3: Drip irrigation system that can be remotely controlled over the phone, with sensors to measure soil moisture and nutrient content(if possible), and camera to see if everything looks ok or not from a remote location.__

Motivation for idea: Everytime we travel, we have to rely on our parents to come by to water the plants. Instead, if there was a system that allowed for watering the plants remotely, it would be a lot more convenient.

Has it been already done? If so, is my work going to add any additional value to an existing one or is it going to be a replication?

Yes, there is nothing novel about it. Many gardens have been set up like this, with a remote-controlled drip irrigation system, like this one on instructables. However, for me it’ll be a new problem that I will be solving for my own garden needs.

What is it going to look like? (A sketch)

__Idea 4: Sound proof, noise cancelling headphones__

Motivation for idea: Every time M works out of a co-working space, or even from our home, he complains about the myraid types of noises that are distracting to him – like, people talking, coffee machine whirring, dog barking, train horn etc. He keeps wishing there was a solution that worked much like a helmet and he could wear it to cancel out all noises and work in a quiet environment.

Has it been already done? If so, is my work going to add any additional value to an existing one or is it going to be a replication?

There are noise cancelling headphones but I think they cancel out a specific frequency or type of noise alone and not all noises. For instance, the noise-cancelling headphones that M currently uses cancels out the noise the jet engine noise on an airplane, but does nothing in a co-working space.

What is it going to look like? (A sketch)

I haven’t designed this yet, but maybe it has to look like a helmet so provide that type of silence.

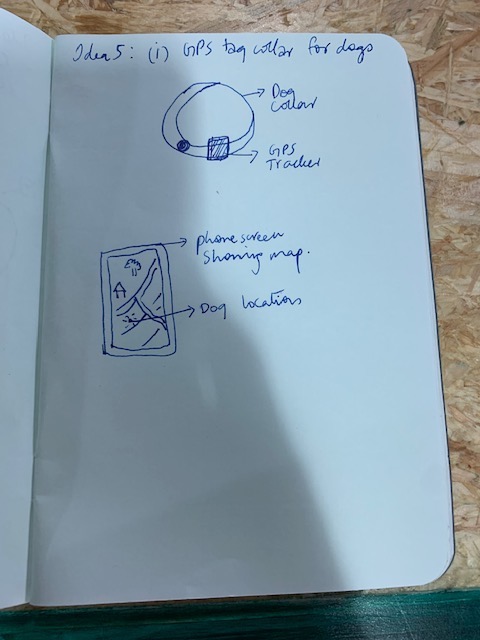

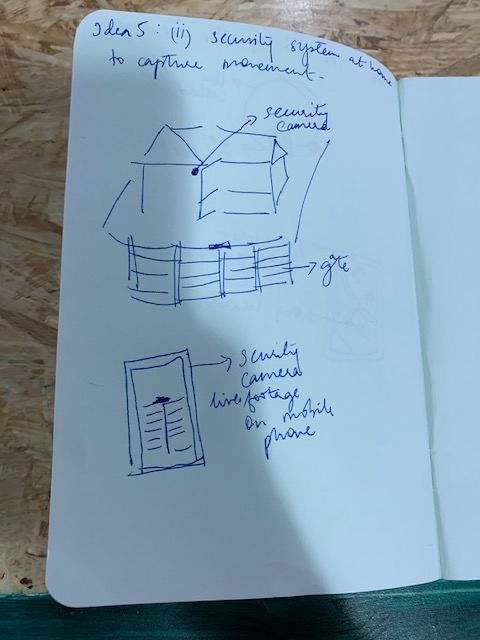

__Idea 5: (i) Cheap GPS tag collar for dogs that can help track their movement, (or) (ii) A security system that can capture movement around a home to know what’s happening there when the owners are not at home__

Motivation for idea: (i) GPS collar - My parent’s dog has a habit of running away every time someone opens the gate. So when they travel, and leave him behind, they are worried someone may inadvertently open the gate and let him out. In these circumstances, it would be good for them to have a way to track him when they are travelling. So whenever they want to know where he is, they can tell whether he is within the compound or has escaped; even if he does escape, they’ll be able to track him. (ii) Security-camera system -

Has it been already done? If so, is my work going to add any additional value to an existing one or is it going to be a replication?

Yes, but most of the GPS trackers are expensive, like this one on amazon that costs INR 11,000 (USD 160). I want to see if I can make a cheaper and smaller version of this tracker.

What is it going to look like? (A sketch)

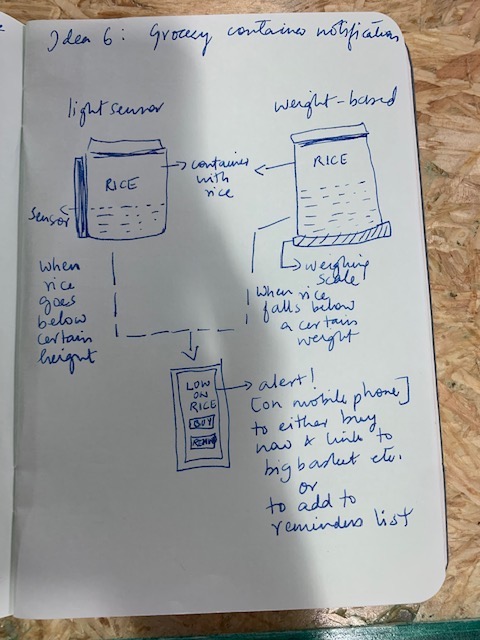

__Idea 6: Grocery container notification__

Motivation for idea: In the kitchen pantry, I often lose track of how much of a particular grain or pulse is available – only when it gets over do I realise that I have to replace it. I wish there was a mechanism that can alert me if the grain or pulse was below a certain quantity so I can immediately purchase it.

Has it been already done? If so, is my work going to add any additional value to an existing one or is it going to be a replication?

To my knowledge, I don’t think there is any product or service that currently tells if the grain/pulse or any grocery in the pantry is over or not.

What is it going to look like? (A sketch)